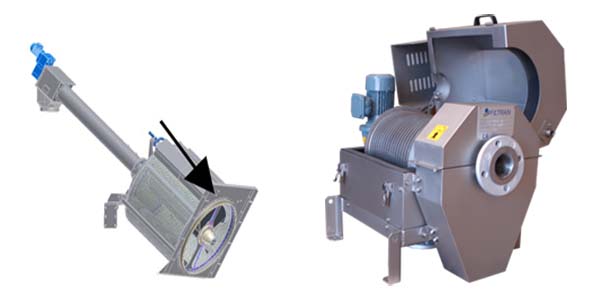

Rotary Drum Screen

The Rotary Drum Screen by Purecreek Environmental Services is a robust and efficient solution for the mechanical separation of solids from wastewater. Designed for municipal and industrial applications, it provides continuous operation, high screening efficiency, and reduced maintenance.

Applications

- Municipal wastewater headworks and pumping stations

- Industrial wastewater treatment (food & beverage, pulp & paper, textile, petrochemical)

- Pretreatment for biological reactors, DAF systems, and membrane filtration units

- Protection of pumps, pipelines, and downstream equipment

How It Works

Wastewater flows into the drum, which is fitted with a perforated plate or wedge wire mesh. As the drum rotates, solids are retained on the surface while the liquid passes through. Collected solids are transported and discharged by internal flights, while the drum is continuously cleaned with brushes or high-pressure spray nozzles, ensuring uninterrupted operation.

Models & Options

- Screen Elements: perforated plate (0.5–6 mm openings), wedge wire

- Configurations: channel-mounted or tank-enclosed versions

- Materials: Stainless steel AISI 304 / 316 (standard), corrosion-resistant coatings available

- Custom Designs: flow rates up to 1000 m³/h with variable drum diameters and lengths

Technical Specifications (example values, customizable)

|

Parameter |

Value / Options |

|

Flow capacity |

up to 1000 m³/h |

|

Screen opening sizes |

0.5–6 mm (customizable) |

|

Drum diameter |

300–2000 mm (depending on model) |

|

Drive power |

0.5–5 kW |

|

Cleaning system |

Brush and/or spray nozzles |

|

Material of construction |

Stainless steel 304 / 316 |

Key Benefits

- Continuous solids separation with high screening efficiency

- Automatic cleaning reduces manual labor and downtime

- Durable stainless steel construction for long service life

- Customizable sizes and capacities for municipal and industrial needs

- Compact design allows easy retrofit in existing plants

Compliance

Purecreek rotary drum screens are designed in collaboration with SEFT Group and built to meet Canadian standards (CSA, UL, ETL).

Case Reference

At an industrial food processing facility, the installation of a rotary drum screen reduced suspended solids by over 60%, significantly lowering downstream treatment costs and maintenance requirements.

Maintenance & Operation

- Minimal maintenance required thanks to automatic cleaning

- Easy access to screen elements for inspection or replacement

- Designed for safe and reliable operation with protective covers

Call to Action

👉 Contact Purecreek Environmental Services to request technical datasheets or a customized rotary drum screen solution for your wastewater treatment needs.